Tunnel Vision Hoops Spring Wire Channel vs Their Spring Wire Channel | Testing and Comparing Plastic Attachment Channels

We decided to take a closer look at one of the best selling greenhouse plastic attachment channels from one of our competitors. We bought it, and then compared it against the single aluminum channel and wire we sell; we wanted to determine what is the best spring wire / wiggle poly lock channel on the market.

If our channel and wire out-tests this competitor of ours, we'll know where we stand...on top ;).

We did some extensive testing, and we got some SUPER interesting answers.

Comparing Channels and Wire

There are various ways to compare the channel + wire, and here are the tests we did:

- Compared the competitors posted specs for length, width, and height: Some places state the channels' specs... are they really what they say?

- We compared their wall thicknesses: Wall thickness determines how rigid the channels are, and is VERY important for strength.

- Stress Test / Torque Test: We manually tried rotating the channels with our hands to see how they handled torque.

- We used spring wires and then soaked them in water to test their longevity: Do they rust, does coated wiggle spring wire degrade? We wanted to see how these did over time.

Comparing Just the Channel Base

Let’s begin with the base product, the single aluminum channel ONLY. This test didn't have anything to do with the wire. Instead, we wanted to focus on the actual unit used to hold plastic... the channel.

Length, Width, and Wall Thickness

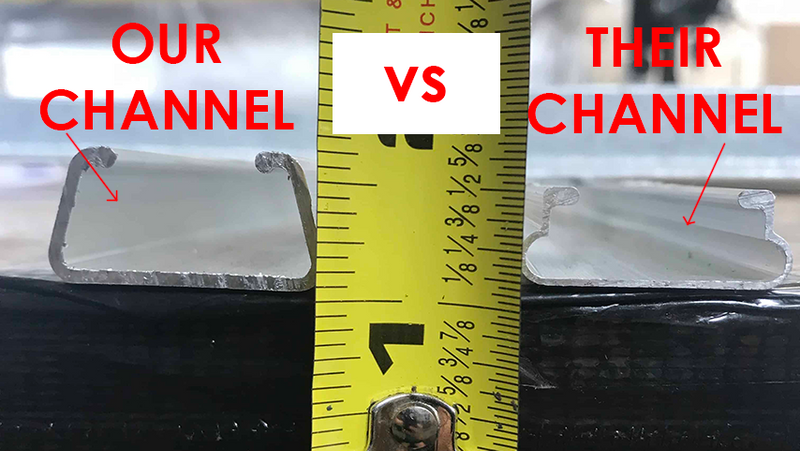

Let's start by comparing the specs for the Tunnel Vision Hoops' single channel vs the competitors' channel:

| Tunnel Vision Hoops LLC Channel | Competitor's Channel | |

| Length | 72" | 72" |

| Width | 1.25" | 1.19" |

| Height | 0.625" | 0.43" |

| Wall Thickness | 1/16" | 1/32" |

The competitions' base specs were supposed to be the same as ours... but when we received the sample, we realized the ACTUAL dimensions did not match what was advertised:

First, this means the competitor was disingenuous about what they were selling.

Second, while these discrepancies seem minor, the results are a poorer quality product.

This poorer product can more easily be twisted and bent.

Being able to twist and bend this material means that it ultimately leads to reduced structural integrity, and an inability to withstand adverse weather.

You can see in the picture above, that our competitors' thinner walled single-aluminum channel BENDS under simple hand torque.

Even when attaching single aluminum channel to lumber or bow framing, the channel itself is what is holding poly to your structure, and poly takes the brunt of wind and storm damage.

RELATED: 4 Ways to Attach Greenhouse Plastic to a Metal Frame

When gusts put enough force on greenhouse plastic, especially if multiple wires are securing the poly, the force moves to the channel and the screws attaching it... More durable channel won’t rip through tek screws like a thinner channel could.

This test showed us what we were hoping; our Single Aluminum Spring Wire Channel is made of thicker aluminum, and is true to spec.

Which Holds More Greenhouse Plastic and Wire

The dimensions of the channel are also important when considering how it will be used on your high tunnel. For example, are you covering your structure with one layer of greenhouse plastic, or two?

Our single channel has a higher profile, and thus allow multiple layers of clear 6 mil greenhouse plastic and spring wire... as well as shade cloth. All can be wired in with relative ease.

You can see our channel (above) demonstrating how well, and seamlessly, it can hold three layers of material and three layers of wire.

The competitors channel could not fit multiple layers of both materials due to its lower height profile.

In the end, our channel could hold more plastic and more wire than this leading competitor.

Next... Comparing Spring Wire (Wiggle Wires)

Our wire is four feet in length and double tempered stainless steel, at a 0.85” diameter.

The competitors wire is six and a half feet in length, and only 0.83” diameter. Additionally, their wire is steel coated in PVC.

Comparing Spring Wire Based on Length

We prefer using shorter, 4 ft. long wire, as it is easier to control and reduces the risks of puncturing poly or an eye as the wire wiggles back and forth during installation.

The above being said, 6.5 ft. long wire isn't much different, and in ways a longer wire reduces the amount of time before you need to get the next piece.

So in a sense, we feel there is a "tie" when it comes to the length of the wire.

Coated vs Uncoated Spring Wire

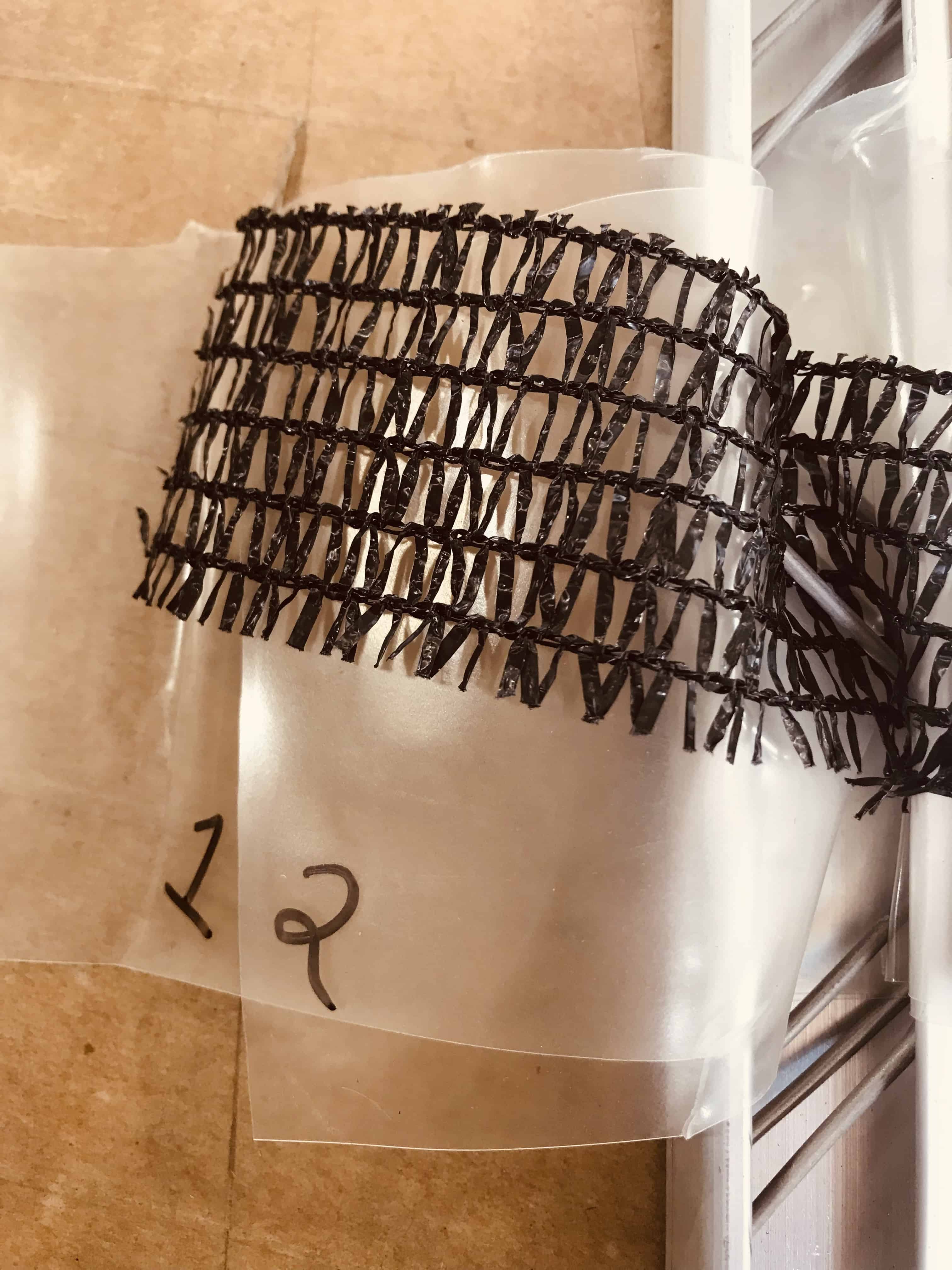

Spring wire coated with PVC has gained a lot of popularity recently, so we thought it would be interesting to compare PVC coated spring wire against stainless steel spring wire.

We made some pretty interesting discoveries after putting both wires to the test.

We found that the PVC coating slides off of the wire with any amount of friction, such as placing it in the channel and then removing it.

This resulted in small locations on the wire where the steel beneath the coating were exposed. These exposed areas ultimately rust.

We Placed a Cut Section of Both Wires Into Water

After 45 Days Submerged

Above shows what the PVC coated spring wire (left) and double tempered stainless steel spring wire (right) look like when left submerged in water for 45 straight days.

As visible from the picture, the end of the PVC coated spring wire has some serious rusting, while the double tempered stainless steel spring wire, has some calcification on its layer that could be more easily wiped away.

Double Channel

To take channel considerations a step further, we carry Double Aluminum Channel made out of the same quality materials as our single channel.

Our double channel is so strong that is can act as hip-rail on its own, without the use of lumber.

Additionally, strong Double Aluminum Channel can much more easily fit two layers of inflated greenhouse poly.

The two different connection locations double channel provides means you'll be able to preserve much more space in the channel that could receive shade cloth, light deprivation, or other covers.

Another added benefit of Double Aluminum Channel is that it means if you top cover gets damaged, you could replace just that top cover, without disturbing the roll-up sides.

In other words, if you are looking for strong single channel, it may make sense to check out Double Aluminum Channel for your side-walls.

The Results are In

Overall we've found our aluminum channel and wire:

- To be most accurately represented in its online description

- To be made of higher quality materials, and

- To be made in dimensions that allow the most versatility and dependability in its use.

The single aluminum channel and wire we carry is the best quality for the price, with double channel an even more advantageous upgrade.

RELATED POSTS:

- 3 Best Backyard High Tunnel Hoop Houses

- 10 Crucial Building Components for High Tunnel Hoop Houses

- 5 Benefits of a Dedicated Seed Starting Greenhouse

- 9 Highly Profitable Winter High Tunnel Hoop House Crops

- Best Shade Cloth for High Tunnel Tomato Production

- 5 Ways to Insulate Your Greenhouse

- High Tunnel Roll-up Sides - Benefits, Hardware, Installation